What Is Parawood? The Hidden Gem of Sustainable Furniture

If you have been shopping for furniture lately—perhaps looking for a sturdy dining table, a sleek nightstand, or a solid wood dresser—you have likely stumbled upon the term “Parawood.”

It is everywhere in modern furniture showrooms, often praised for its durability and affordable price tag. Yet, for many consumers, the name remains a mystery. Is it real wood? Is it a cheap composite? Is it durable enough for a busy household?

The short answer is: Yes, it is real, solid hardwood, and it is one of the most underrated materials in the woodworking industry today.

In this comprehensive guide, we will peel back the bark to reveal exactly what Parawood is. We will explore its botanical origins, how it transforms from a latex-producing tree into high-end furniture, and why it might just be the best eco-friendly choice for your home.

Defining Parawood: The Botanical Origin

To understand Parawood, we must first look at its source. Parawood is the lumber derived from the Pará rubber tree, scientifically known as Hevea \ brasiliensis.

You may know it better by its common name: Rubberwood.

In the furniture industry, the terms “Parawood” and “Rubberwood” are used interchangeably. Retailers often prefer the term “Parawood” because “Rubberwood” can sometimes confuse customers, leading them to believe the furniture is flexible, synthetic, or made of actual rubber.

Where Does It Come From?

The tree is native to the Amazon basin in Brazil (specifically the Pará state, hence the name). However, today it is predominantly grown in extensive plantations across Southeast Asia, particularly in:

- Thailand

- Malaysia

- Indonesia

- Vietnam

These trees belong to the Euphorbiaceae family. They are fast-growing tropical hardwoods that play a dual role in the global economy: first as a source of natural latex, and second as a source of timber.

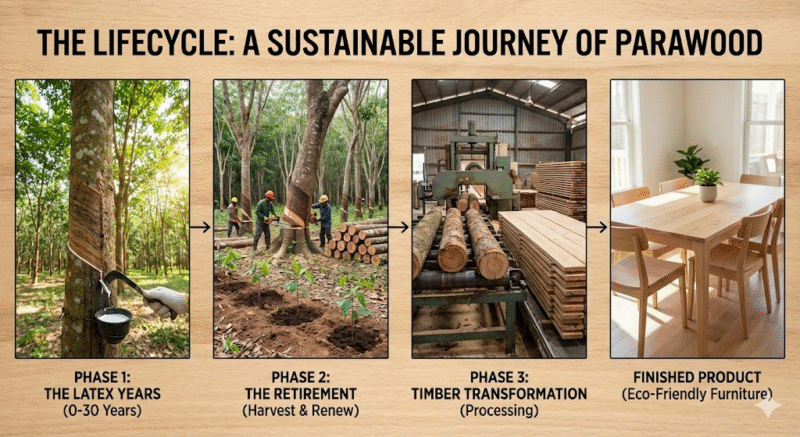

The Lifecycle: A Story of Sustainability

One of the most compelling reasons for Parawood’s rise in popularity is its unique harvesting cycle. Unlike Oak, Maple, or Teak—which are often cut down solely for their timber—Parawood is essentially an agricultural byproduct.

Here is how the lifecycle works:

Phase 1: The Latex Years

The Hevea brasiliensis is planted primarily for the latex sap it produces (the white, milky substance used to make rubber). For the first 25 to 30 years of its life, the tree is tapped regularly. It is a working tree, fueling the tire, glove, and rubber industries.

Phase 2: The Retirement

Eventually, as the tree ages, its latex production dwindles to the point where it is no longer commercially viable. In decades past, these “retired” trees were considered agricultural waste. Plantation owners would cut them down and burn them on the spot to clear room for new saplings. This released massive amounts of carbon into the atmosphere and wasted millions of tons of wood.

Phase 3: The Timber Transformation

In the 1980s, the industry shifted. Woodworkers realized that if treated correctly, this “waste” wood was actually a high-quality, blonde hardwood. Now, when the trees stop producing latex, they are harvested for timber.

Because the trees are replanted immediately to continue the latex cycle, Parawood is considered one of the most eco-friendly woods on the market. No natural forests are cleared to produce it; it utilizes plantation trees that have already served a useful purpose.

Physical Characteristics: What Does Parawood Look Like?

When you look at a piece of Parawood furniture, what are you actually seeing? Understanding its grain and texture helps explain why it finishes so beautifully.

The Color Palette

In its natural state, Parawood is very light. It ranges from a pale cream to a light yellowish-brown. Because of this neutral, blonde base, it is a favorite among furniture manufacturers—it acts as a blank canvas. It can be stained to look like Walnut, Cherry, or Mahogany with relative ease.

The Grain

The grain of Parawood is generally straight and open, though it can sometimes be interlocked. It has a coarse texture that is somewhat similar to Oak, but without the intense, distinct grain patterns that Oak is famous for. This makes it ideal for modern furniture where a clean, uniform look is desired.

The Hardness (Durability)

Do not let the name “Rubberwood” fool you—this is not a soft material. It is a genuine hardwood.

On the Janka Hardness Scale (the industry standard for measuring the resistance of wood to denting and wear), Parawood ranks around 960 to 990 lbf.

- Comparison: It is harder than Radiata Pine and Alder.

- Comparison: It is similar in hardness to Black Cherry, Teak, and Soft Maple.

- Comparison: It is slightly softer than Red Oak (which is around 1290 lbf).

This places Parawood in the “Goldilocks zone” for furniture: hard enough to resist scratches and dents from daily use, but not so hard that it is difficult for woodworkers to cut and shape.

The Manufacturing Process: From Plantation to Living Room

Processing Parawood requires a specific set of steps that differ slightly from other lumber. Because the wood is rich in starches and sugars (a remnant of the latex production), it is highly attractive to fungi and insects in its raw form.

To make it furniture-grade, it undergoes a rigorous process:

- Immediate Processing: Once the tree is felled, it must be transported and processed quickly to prevent blue stain fungus from setting in.

- Pressure Treatment: The wood is pressure-treated with preservatives (often boron-based compounds) to neutralize the sugars and make the wood immune to insect attacks and rot.

- Kiln Drying: The wood is placed in large kilns to reduce its moisture content. This is a critical step. Kiln drying stabilizes the wood, ensuring that it won’t warp, crack, or split once it is turned into furniture.

Once it leaves the kiln, Parawood is a stable, seasoned lumber ready for construction.

The Pros and Cons of Parawood

Like any material, Parawood has its strengths and weaknesses. Being an informed buyer means knowing what this wood can and cannot do.

The Advantages (Pros)

- Cost-Effectiveness: Because Parawood is a byproduct of the rubber industry, the raw material is abundant and cheaper than primary timber like Oak or Walnut. This allows you to buy solid wood furniture at a price point often associated with veneers or MDF.

- Eco-Friendliness: As mentioned, it uses “waste” wood and prevents deforestation of virgin rainforests.

- Workability: It holds nails, screws, and glue exceptionally well. For DIYers, it cuts smoothly and sands down to a nice finish.

- Staining Versatility: Its pale color takes stains uniformly. You can easily match Parawood chairs to an existing Oak or Mahogany table by choosing the right stain.

- Durability: It is dense and strong, making it suitable for high-traffic items like dining chairs, tabletops, and children’s furniture.

The Disadvantages (Cons)

- Indoor Use Only: This is the biggest limitation. Parawood is not rot-resistant by nature. Despite the treatment process, it absorbs moisture easily. If you leave a Parawood chair outside in the rain, it will eventually warp and rot. It is strictly an indoor wood.

- Blotching Risk: While it stains well generally, like Pine or Maple, it can sometimes absorb stain unevenly (blotching) if not treated with a pre-stain wood conditioner first.

- Latex Allergies (Rare): There is a common myth that Parawood triggers latex allergies. In reality, the kiln-drying process removes the proteins that cause reactions. However, those with severe anaphylactic latex allergies are sometimes advised to exercise caution, though reported cases of reaction to the finished wood are statistically nonexistent.

Parawood vs. The Competition

How does Parawood stack up against the heavy hitters of the furniture world?

Parawood vs. Oak

Oak is the king of traditional furniture. It is harder than Parawood and has a very distinct, swirling grain pattern.

- Verdict: If you love heavy grain texture, choose Oak. If you want a smoother, more modern look (and want to save money), choose Parawood.

Parawood vs. Pine

Pine is a softwood. It dents very easily (you can dent it with a fingernail). It also has “knots” that can bleed sap.

- Verdict: Parawood is superior to Pine for furniture. It is much harder, has fewer knots, and looks more sophisticated.

Parawood vs. MDF/Particle Board

MDF is engineered wood (sawdust and glue). It is heavy, hates water, and cannot be repaired if chipped.

- Verdict: Parawood is solid wood. It is infinitely stronger than MDF. If a Parawood table gets scratched, you can sand and refinish it. If MDF gets damaged, it is usually ruined.

Common Uses for Parawood

Because of its versatility, you will find Parawood in almost every room of the house.

Dining Room Furniture

This is the most common application. Parawood is used extensively for table legs, chair backs, and solid table surfaces. Its resistance to warping makes it a reliable choice for large flat surfaces like dining tables.

Kitchen Cabinetry

Parawood is often marketed as “Eco-Wood” in cabinetry. It holds paint exceptionally well, making it a top choice for painted kitchen cabinets (white, grey, or navy blue).

Children’s Furniture

Because it is durable, non-toxic (after processing), and shock-resistant, it is frequently used for cribs, bunk beds, and toy chests.

Home Accessories

You will also find Parawood in:

- Cutting boards (it is dense and doesn’t dull knives quickly).

- Bar stools.

- Office desks.

- Flooring (though less common than furniture due to moisture concerns).

Maintenance: How to Care for Parawood

Caring for Parawood is simple and aligns with standard solid wood care practices. If you treat it right, it can last for generations.

Daily Cleaning

- Dust Regularly: Use a soft, lint-free cloth.

- Spills: Wipe up liquid spills immediately. Do not let water sit on the surface, as the wood pores can absorb it, leading to white spots or swelling.

- Soap: Use a mild soap and water solution for sticky messes, but dry the area immediately after.

What to Avoid

- Direct Sunlight: Like all wood, prolonged exposure to harsh UV rays can cause the wood to fade or the finish to crack.

- Heat Sources: Do not place Parawood furniture directly next to a radiator or heating vent. The dry heat can suck the moisture out of the wood, causing it to split.

- Harsh Chemicals: Avoid ammonia-based cleaners or sprays containing silicone, as they can damage the lacquer finish over time.

A Guide for the DIY Enthusiast

If you are a hobbyist looking to build a project, you can often buy Parawood lumber (sold as Rubberwood) at specialty lumber yards.

Tips for Working with Parawood:

- Sawing: It saws easily but can dull blades moderately quickly due to the silica content sometimes found in tropical woods. Use carbide-tipped blades.

- Sanding: It sands very smoothly. Start with 120 grit and move up to 220 grit for a glass-like surface.

- Finishing:

- Paint: Parawood is excellent for painting because it doesn’t have deep grain crevices that need filling.

- Stain: Always use a “Pre-Stain Conditioner” before applying dark stains to ensure an even color.

- Top Coat: Polyurethane or lacquer works beautifully to seal the wood.

Conclusion: Is Parawood Right for You?

Parawood represents a sweet spot in the modern furniture market. It bridges the gap between cheap, disposable particle board furniture and expensive, luxury hardwoods like Walnut or Teak.

You should choose Parawood if:

- You want solid wood furniture without the premium price tag.

- You care about sustainability and reducing deforestation.

- You need durable furniture for a family environment.

- You prefer a smooth, consistent grain over rustic, knotty textures.

You should avoid Parawood if:

- You are looking for outdoor patio furniture (choose Teak, Acacia, or Cedar instead).

- You specifically want the heavy, open grain look of Oak or Ash.

Ultimately, Parawood is not just a “substitute” wood; it is a high-performance material in its own right. By turning an agricultural byproduct into beautiful, long-lasting heirlooms, Parawood proves that style, durability, and eco-consciousness can go hand in hand.

Frequently Asked Questions (FAQ)

Is Parawood real wood?

Yes, Parawood is 100% solid hardwood derived from the Pará rubber tree.

Is Parawood toxic?

No. While the raw wood is treated to prevent pests, the finished furniture is sealed and safe for home use, including children’s furniture.

Can I paint over finished Parawood furniture?

Yes! Parawood takes paint very well. Just be sure to lightly sand the existing finish (scuff sand) and use a high-quality primer before painting.

How long does Parawood furniture last?

With proper care (keeping it dry and indoors), Parawood furniture can last 20 years or more, easily becoming a generational piece.

Hi, I’m Charles Larson. We do everything we can to support our readers with hundreds of hours of research and comparison testing to ensure you find the perfect tool for your workshop.