Meta Description: Master woodworking safety with this comprehensive guide. From essential PPE and preventing kickback to tool-specific rules, learn how to keep your shop accident-free.

Woodworking is a deeply rewarding craft—there is nothing quite like taking a rough piece of timber and shaping it into a functional piece of art. However, the machines that make this possible are indifferent to what they cut, whether it’s White Oak or a finger.

According to recent consumer product safety statistics, table saws alone account for over 30,000 injuries annually, with medical costs estimated at over $2 billion per year. These aren’t just statistics; they are seasoned woodworkers, hobbyists, and students whose lives were changed in a split second.

The difference between a master craftsman and an injured novice isn’t just skill—it’s a disciplined adherence to woodworking safety rules. Safety is not an accessory you put on; it is the most important tool in your arsenal.

This guide will cover everything you need to know to rank safety as your #1 priority. We will dive into the essential personal protective equipment (PPE), the “Golden Rules” of the shop, and specific strategies to avoid the most common injuries.

The Golden Rules of Woodworking

Before you even touch a power switch, there are foundational behaviors that must be ingrained in your workflow. These rules apply to every project, every tool, and every minute you spend in the shop.

1. The “Disconnect Power” Rule

This is arguably the most violated rule in the shop. whenever you are changing a blade, bit, or cutter, disconnect the power. It is not enough to just switch the tool off. Switches can fail, or you might accidentally bump one while wrenching on a blade nut.

- The Habit: Unplug the tool and put the plug on the workbench where you can see it. This gives you visual confirmation that the tool is dead.

2. No Distractions, Ever

Woodworking requires a “flow state” of concentration. If you are tired, angry, or distracted, you are dangerous.

- Phone Policy: Leave your phone in a drawer or on “Do Not Disturb.” A sudden ringtone can startle you while you are feeding stock into a blade.

- The 3-Foot Rule: If someone enters your shop, they should not approach within 3 feet of you while a machine is running. Establish a rule that they must wait for you to turn the machine off and make eye contact before speaking.

3. Dress for Safety (The “No Loose Items” Policy)

Rotating machinery loves to grab loose fabric. The torque of a 3HP motor will pull you in faster than you can react.

- Roll Up Sleeves: Long sleeves should be rolled above the elbow.

- Remove Jewelry: Rings, watches, and bracelets are strictly prohibited. A ring can get caught on a protrusion and deglove a finger (a horrific injury you want to avoid).

- Tie Back Hair: Long hair must be tied back and secured.

4. Sharp Tools Are Safe Tools

It sounds counterintuitive, but a dull blade is far more dangerous than a sharp one. A dull blade requires you to use more physical force to push the wood through. Pushing harder increases the likelihood of your hand slipping or the workpiece binding and kicking back.

- Maintenance: Clean your blades of pitch and resin regularly, and send them out for sharpening the moment you notice burn marks on your wood.

Personal Protective Equipment (PPE) – The Non-Negotiables

You cannot rely on your reflexes to save you. PPE is your last line of defense when things go wrong.

Eye Protection: Your Most Vital Asset

Wood chips fly at high velocities. Standard prescription glasses are not safety glasses.

- Requirement: Look for glasses with the ANSI Z87.1 rating. This indicates they have been impact-tested.

- Face Shields: When using a lathe or router, chips don’t just fly forward; they fly everywhere. A full-face shield is mandatory here to protect your entire face from high-velocity debris.

Hearing Protection: The Silent Danger

Hearing loss is cumulative and permanent. The noise from a router or planer can easily exceed 100 decibels (dB). OSHA standards suggest hearing damage can occur after just 15 minutes of exposure at 100 dB.

- Earplugs vs. Muffs: Expanding foam earplugs are great, but over-ear muffs are often easier to put on and take off, encouraging more frequent use. Look for a Noise Reduction Rating (NRR) of at least 25 dB.

Lung Protection: Wood Dust is Toxic

Many woodworkers ignore this, but wood dust is a known carcinogen. Fine dust (under 10 microns) stays in the air for hours and settles deep in your lungs.

- Dust Masks: An N95 mask is the minimum standard.

- Respirators: For exotic woods (like Cocobolo or Rosewood) which can cause severe allergic reactions, or when applying finishes, use a half-face respirator with P100 filters.

Tool-Specific Safety Guides

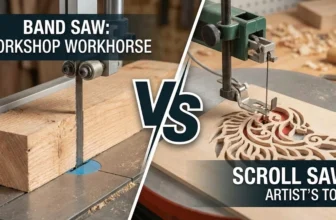

Different tools require different respect. Here is how to handle the “Big Three” in the shop.

1. Table Saw Safety

The table saw is the heart of the shop and the most common source of serious injury.

- Avoid the “Line of Fire”: Never stand directly behind the blade. If the wood kicks back, it will launch straight back. Stand to the left of the blade.

- Use a Riving Knife: This is the single most important safety feature on a modern saw. It prevents the wood from pinching the back of the blade, which is the #1 cause of kickback. Never remove it.

- Push Sticks: If your hand is going to be within 6 inches of the blade, use a push stick or push block.

2. Router Table Safety

Routers spin at 20,000+ RPM. They don’t cut; they pulverize.

- Feed Direction: Always feed against the rotation of the bit. If you feed with the rotation (climb cutting), the router can rip the wood out of your hands and pull your fingers into the bit.

- Take Shallow Passes: Don’t try to cut a 1/2″ profile in one go. Make multiple shallow passes to reduce strain on the bit and the risk of the wood grabbing.

3. Miter Saw (Chop Saw) Safety

Because the wood is stationary, people get complacent with miter saws.

- Cross Your Hands Rule: Never cross your arms to hold a piece of wood. If the handle is on the left, use your left hand. If you cross your arms, your holding hand is dangerously close to the blade path.

- Wait for the Stop: After making a cut, hold the saw head down and wait for the blade to stop spinning before you lift it. Lifting a spinning blade can catch the off-cut and launch it across the room.

When drilling holes and cutting materials, you need to make sure that the saw and drill are fitted with sharp blades and bits

Understanding and Preventing Kickback

If you want to rank for woodworking safety, you must address kickback. It is the boogeyman of the woodshop, but it is entirely preventable with physics.

What is Kickback?

Kickback occurs when the back of a spinning saw blade (the part coming up out of the table) catches the workpiece. Because the teeth are moving upward and toward you, they lift the wood off the table and throw it back at the operator at speeds of up to 100 mph.

How to Prevent It

- Riving Knife/Splitter: As mentioned, this keeps the kerf (the cut slot) open so the wood can’t pinch the blade.

- Flat and Straight Stock: Never cut twisted, cupped, or bowed wood on a table saw. The irregularity can cause the wood to rock and bind against the blade.

- The Fence Rule: Never use the rip fence as a stop block when cross-cutting (cutting across the grain). The off-cut will get trapped between the blade and the fence and will kick back.

The “Silent” Hazards: Drugs, Alcohol, and Fatigue

The Zero Tolerance Policy

This should go without saying, but alcohol and power tools never mix. Even one beer can slow your reaction time enough to turn a near-miss into an amputation. Save the drink for when the sawdust has been swept up and the lights are off.

The “Gut Check”

Fatigue is a major cause of accidents. If you find yourself making simple mistakes, measuring incorrectly, or feeling frustrated, stop.

- The 3-Attempt Rule: If you try to fit a joint three times and it’s still not working, walk away. Frustration leads to forcing the tool, and forcing the tool leads to injury.

Workshop Environment & Housekeeping

A messy shop is a dangerous shop. Workshop organization is a critical component of safety.

Lighting

You cannot be safe if you cannot see. Shadows can hide fingers or obscure cut lines.

- Task Lighting: Install dedicated lights over your main tools (bandsaw, drill press, lathe).

- LED Upgrades: Replace humming, flickering fluorescent bulbs with bright, cool-white LEDs.

Air Quality and Ventilation

We discussed masks, but ambient air quality matters too.

- Dust Collection: Connect a vacuum or dust collector to your tools.

- Air Filtration: An overhead air filter can cycle the air in your shop to remove the fine, invisible dust that lingers for hours.

Trip Hazards

Extension cords are a classic trip hazard.

- Cable Management: Run cords along the ceiling or tape them down if they must cross a walkway.

- Floor Maintenance: Sawdust is slippery. Sweep your floor regularly, especially around the table saw area where footing is vital.

A Safety Checklist for Every Project

Before you start your next build, run through this quick mental checklist. (This section is great for printing out and hanging in your shop).

Pre-Start Checklist:

- Mental Check: Am I awake, alert, and sober?

- PPE Check: Safety glasses on? Hearing protection ready? Dust mask available?

- Clothing Check: Sleeves rolled? Jewelry off? Hair tied?

- Machine Check: Is the blade sharp? Is the riving knife installed? Is the cord free of damage?

- Workspace Check: Is the floor clear of scraps? Is the lighting adequate?

FAQ: Common Woodworking Safety Questions

To help you find the specific answers you need, we’ve compiled the most frequently asked questions about woodworking safety.

What is the most dangerous tool in a woodshop?

Statistically, the table saw causes the most injuries due to its frequent use and exposed blade. However, the shaper and jointer are often considered more dangerous per hour of use because they can pull hands into the cutterhead very quickly.

Can I wear gloves while woodworking?

Generally, NO. You should never wear gloves while operating rotating machinery (table saw, jointer, lathe, drill press). The fabric can snag on a spinning bit or blade and pull your hand into the machine, causing severe crushing or avulsion injuries. Gloves are only for handling rough lumber away from machines.

What should be in a woodshop first aid kit?

A standard home kit isn’t enough. You need a kit designed for trauma.

- Tourniquet: For stopping severe bleeding from an amputation or deep laceration.

- Pressure Bandages: To wrap deep cuts.

- Eye Wash: To flush out sawdust or chemicals.

- Splinter Removal Tools: High-quality tweezers and a magnifying glass.

How do I use a push stick properly?

A push stick should be used to push the wood down and forward simultaneously. Use a “shoe” style push stick (which looks like a handle with a long heel) rather than a simple stick, as it gives you more control over the wood and keeps your hand higher above the blade.

Conclusion: Safety is a Mindset

Woodworking is a journey of lifelong learning. You will learn new joinery techniques, new finishes, and new design styles. But the one constant must be your commitment to safety.

Remember, a project can always be built again. Wood is renewable. Your fingers, eyes, and lungs are not. By following these woodworking safety rules, respecting your machines, and keeping your focus sharp, you ensure that you can enjoy this craft for decades to come.

Stay safe, and happy building.

Hi, I’m Charles Larson. We do everything we can to support our readers with hundreds of hours of research and comparison testing to ensure you find the perfect tool for your workshop.