Concrete is one of the strongest and most widely used construction materials in the world. But to make concrete even more durable, especially in structures that must handle heavy loads, builders place reinforcing steel bars, known as rebar, inside the concrete before it hardens. This combination is called reinforced concrete.

Rebar does an important job:

It helps the concrete resist cracking, bending, and structural failure. So whenever you drill into walls, floors, driveways, foundations, or beams, there is a good chance you may encounter steel reinforcement inside the slab.

However, hitting rebar while drilling can be challenging for both beginners and experienced contractors. Regular masonry bits are designed to cut through concrete—not steel—so when they hit rebar, they overheat, dull quickly, or even break. This can cause delays, wasted materials, or worse, damage to the structure.

This guide will teach you how to drill through concrete that contains rebar the right way, with professional safety methods, proper tools, and efficient drilling techniques. We’ll walk through each step in detail, so you’ll know exactly:

- How to detect rebar before drilling

- How to drill into concrete safely

- What to do when you hit rebar

- Which bit to use when switching from concrete to metal

- How to avoid damaging tools or the structure

Whether you are a DIY enthusiast working on home improvement or a professional contractor drilling through concrete in large-scale projects, these methods will help ensure a smooth, safe, and successful result.

Safety First: Protect Yourself and the Structure

Before beginning any drilling operation, safety is your top priority. Reinforced concrete drilling involves dust, flying debris, impact vibration, and high heat. These conditions can cause injuries if not handled correctly.

Wear the Right Safety Gear

| Gear | Why It’s Important |

| Safety Goggles | Protect your eyes from dust and flying concrete chips. |

| Gloves | Improve grip and protect hands from vibration and heat. |

| Dust Mask or Respirator | Prevent inhalation of concrete dust (which may contain silica). |

| Ear Protection | Hammer drills and rotary hammers are very loud. |

| Steel-Toe Boots (optional but recommended) | Protect your feet from falling tools or concrete fragments. |

Concrete dust, especially silica dust, can harm the lungs over time. So always wear a dust mask or respirator when drilling.

Identify Rebar Before You Start

Drilling blindly into reinforced concrete without checking for embedded steel is risky. You could:

- Hit a structural rebar that must not be cut

- Damage electrical conduits hidden inside the concrete

- Waste time and burn out drill bits

To avoid this, use one of the following rebar detection tools:

- Rebar Locator / Scanner (Concrete Scanner)

- Uses electromagnetic signals to locate steel reinforcement.

- Common models: Bosch, Hilti, and DeWalt concrete scanners.

- Ideal for professional work.

- Uses electromagnetic signals to locate steel reinforcement.

- Stud Finder with Metal Detection Mode

- Cheaper and simpler.

- Useful for shallow wall drilling (not reliable for deep slabs).

- Cheaper and simpler.

- Construction Plans

- Review building plans when available to identify rebar grid patterns.

- Review building plans when available to identify rebar grid patterns.

If rebar is detected, mark the drilling point with chalk, a marker, or masking tape so you can adjust your drilling strategy accordingly.

Tools You’ll Need

To drill through reinforced concrete successfully, you need tools built for power and durability. Using the wrong tools is the #1 cause of broken bits and burned-out drills.

1. A Hammer Drill or Rotary Hammer

- Hammer Drill (for light to medium jobs)

- Good for walls, small holes, and home repairs.

- Works by combining rotation with rapid hammering to break concrete.

- Good for walls, small holes, and home repairs.

- Rotary Hammer (for heavy-duty drilling)

- Much more powerful.

- Ideal for drilling floors, slabs, beams, and thick concrete.

- Much more powerful.

If you expect to hit rebar, a rotary hammer is strongly recommended.

2. Masonry Drill Bits for Concrete

Start drilling concrete using a carbide-tipped masonry bit.

Choose the correct SDS, SDS Plus, or SDS Max bit depending on your drill model.

These bits:

- Cut concrete efficiently

- Are resistant to abrasion

- Work best with hammering action

However, they cannot cut through rebar. Once you hit steel, you must switch to a metal-cutting bit.

3. Rebar-Cutting Drill Bit

To penetrate steel reinforcement, use a special rebar-cutting bit, such as:

| Rebar Cutting Bit Type | Description |

| TCT (Tungsten Carbide Tipped) Rebar Bit | Strong enough to cut through embedded steel. |

| SDS Rebar Cutter Bit | Designed specifically for use with rotary hammers. |

| Cobalt / HSS Drill Bit (for smaller holes) | Works in a pinch, slower progress. |

These bits are built to handle metal, not concrete.

So the drilling process will involve switching bits mid-operation.

4. Water for Cooling and Dust Control

Metal and masonry bits heat up quickly.

To prevent damage:

- Drip or spray water onto the drill site while cutting steel.

- This cools the bit and reduces airborne dust.

Never pour excessive water—just enough to keep the bit cool, not soaked.

5. Optional (But Very Useful): Vacuum or Dust Extractor

A vacuum paired with drilling helps:

- Keep the workspace clean

- Prevent inhaling concrete dust

- Improve visibility during drilling

Even a household shop vac works, though professional dust extractors are better.

Summary of Required Tools

| Tool | Purpose |

| Hammer Drill / Rotary Hammer | Primary drilling machine |

| Carbide-Tipped Masonry Bit | For drilling concrete |

| Rebar Cutter / TCT / SDS Rebar Bit | For drilling through steel |

| Rebar Locator / Scanner | To find rebar before drilling |

| Water Source | Cooling and dust reduction |

| PPE (gloves, goggles, mask, ear plugs) | Safety protection |

Full Step-by-Step Drilling Process

This section will walk you through the complete procedure of drilling through concrete that contains rebar — from detection to final hole finishing. Follow each step carefully to avoid damaging tools, weakening the structure, or wasting time.

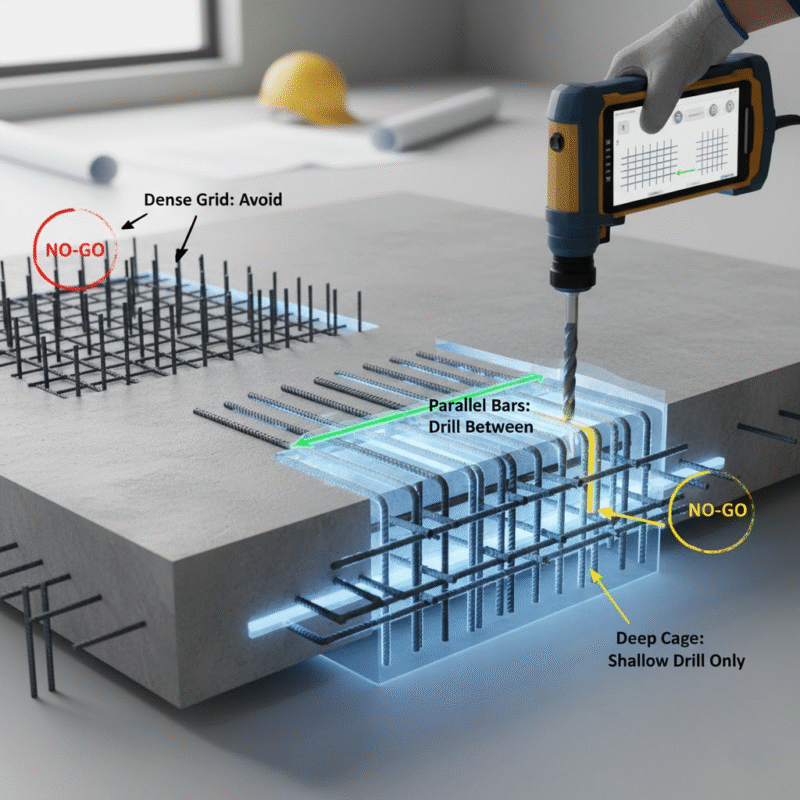

Step 1: Detect Rebar Before Drilling

Before drilling, it’s important to check whether rebar is present near your planned drill point.

Use one of the following methods:

- Use a Rebar Scanner

- Turn the scanner on and hold it flat against the concrete surface.

- Slowly move it in a grid pattern (up-down and left-right).

- When the scanner detects steel, it will beep or display a metal marker.

- Mark these positions with a pencil or chalk.

- Turn the scanner on and hold it flat against the concrete surface.

- Check Building Plans (If Available)

- Reinforced concrete typically uses a grid formation.

- Walls may have rebar placed vertically and horizontally about every 6–18 inches.

- Slabs usually contain mesh or bar mat reinforcement.

- Reinforced concrete typically uses a grid formation.

- Drill a Pilot Hole to Confirm

- Drill a shallow hole (1/4 inch deep).

- If you feel resistance and metallic vibration, you likely hit rebar.

- Drill a shallow hole (1/4 inch deep).

Why detect first?

To avoid unnecessary stress or drilling into critical load-bearing reinforcement. If the rebar is structurally crucial, drilling through it may weaken the concrete. In such cases, repositioning is the best solution.

Step 2: Begin Drilling the Concrete

Start with your carbide-tipped masonry bit attached to your:

- Hammer drill (light to moderate jobs)

- Rotary hammer (deep holes or heavy concrete)

Instructions:

- Place the drill perpendicular to the concrete surface.

- Hold the drill firmly using both hands to control vibration.

- Start drilling at a moderate speed.

- Allow the hammering function to break concrete gradually.

- Pull the drill back occasionally to remove concrete dust and prevent clogging.

Avoid forcing the drill. Let the tool do the work.

If you smell burning or see smoke, reduce speed and clear dust.

Step 3: Recognize When You Hit Rebar

As you drill deeper, you might eventually contact rebar.

You’ll know because:

| Sign | Meaning |

| High-pitched metallic noise | Drill bit is scraping steel |

| Drill bit stops progressing forward | Rebar is blocking the path |

| Strong vibration in handle | Steel resistance detected |

| Concrete dust stops, and metal flakes appear | Confirmed rebar contact |

Stop immediately.

Continuing with a masonry bit will damage the bit and possibly the drill motor.

Step 4: Switch to a Rebar-Cutting Bit

Once you confirm rebar, change your bit.

- Remove the masonry bit.

- Insert a TCT rebar cutter or SDS rebar cutting bit.

- Set the drill to rotation mode only (turn off hammer function).

- Hammering action can chip the rebar cutter and break it.

- Hammering action can chip the rebar cutter and break it.

Drilling Steel Requires Steady Pressure and Cooling

- Apply slow, steady forward pressure.

- Stop every 10–15 seconds to cool the bit.

- Add water to prevent overheating.

If your drill has adjustable speed:

- Set to low to medium RPM for best control and longevity.

Step 5: Drill Through the Rebar

Continue drilling only through the steel section.

The rebar may be round (common in structural beams and slabs) or grid mesh.

Typical rebar diameter: 8mm to 25mm

Heavier beams can contain thicker bars.

Tip:

If the bit squeals loudly, reduce speed and add lubrication water.

As you pass through the steel:

- The vibration decreases

- Resistance drops suddenly

- The bit will move forward more easily

This means you have successfully penetrated the rebar.

Step 6: Switch Back to Masonry Bit and Resume Drilling Concrete

Once the steel is cleared:

- Remove the rebar cutting bit.

- Reattach your masonry bit.

- Turn the hammer function back on.

- Continue drilling to your desired depth.

You may now proceed at your normal drilling pace.

Step 7: Clear Dust and Finish the Hole

To finish:

- Withdraw the drill slowly to remove debris.

- Clean the hole using compressed air or a vacuum.

- If the hole needs to anchor something (bolt, screw, anchor plug):

- Ensure the interior is dust-free for strong holding power.

- Ensure the interior is dust-free for strong holding power.

Common Mistakes to Avoid

Avoiding common mistakes will extend tool life, improve speed, and prevent damage.

| Mistake | Why It’s a Problem | Correct Approach |

| Using only a masonry bit | Masonry bits are not designed for steel | Switch to a rebar cutter when hitting steel |

| Applying excessive pressure | Causes overheating and bit wear | Let the tool and bit do the work |

| No cooling water | Heat damages bits and drill motor | Apply small amounts of water while drilling |

| Drilling with hammer mode ON when cutting steel | Hammer vibration can break rebar bits | Turn hammer mode OFF for steel drilling |

| Ignoring structural layout | Weakens building support | If unsure, relocate hole or consult a professional |

When to Stop and Call a Professional

Not all concrete drilling should be done DIY — some situations require expert evaluation.

You should stop and consult a structural engineer or contractor if:

- The rebar appears especially large (indicating primary structural support).

- The concrete is part of load-bearing columns, beams, slabs, or foundations.

- You notice cracks or vibration spreading while drilling.

- The drill struggles despite correct technique — rebar may be hardened or tensioned.

Cutting into primary reinforcement can weaken a building, especially in beams and columns that carry load.

When in doubt, stop.

Final Best Practices, Structural Considerations, and Conclusion

By now, you understand the full practical process of drilling through reinforced concrete, including how to detect rebar, switch bits, and maintain tool safety. This final section will help you avoid long-term problems, maintain equipment, and ensure that your drilling work does not compromise structural integrity.

How Reinforcement Patterns Affect Your Drilling Strategy

Rebar is not placed randomly; it follows a structural pattern. Recognizing these patterns helps you avoid unnecessary difficulty.

1. Rebar in Walls

- Vertical bars: Provide tensile strength for loads such as wind and gravity.

- Horizontal bars: Resist cracking and help tie vertical bars together.

Spacing: Typically 6–18 inches apart, depending on structural requirements.

2. Rebar in Floors and Slabs

- Usually arranged in mat grids.

- May include wire mesh + rebar in thicker structural slabs.

- Often closer to the surface than in walls.

3. Rebar in Beams and Columns (Critical)

These elements often have:

- Multiple heavy-diameter reinforcing bars.

- Shear ties (stirrups) wrapping around bars.

Cutting reinforcement in beams or columns is not recommended without an engineer’s approval.

Rule of Thumb:

If the concrete element supports load, be cautious about drilling deep or wide holes.

Advanced Tips for Drilling Reinforced Concrete Efficiently

Whether you’re a DIY user or professional contractor, the following techniques can save time, reduce tool wear, and improve accuracy.

1. Start with a Pilot Hole

Before drilling your final diameter:

- Drill a small guide hole (for example, 5mm or 6mm).

- This stabilizes the bit and reduces wandering.

2. Keep Bits Sharp and Clean

After drilling through steel, rebar-cutting bits can retain heat and metal shavings.

To clean:

- Let the bit cool.

- Brush off debris.

- Wipe lightly with machine oil to prevent rust.

3. Maintain Steady, Even Pressure

Excessive force:

- Overheats bits

- Damages bearings in the drill motor

- Causes chipping in surrounding concrete

Let the drill’s impact and rotation do the work.

4. Use a Depth Stop

Most rotary hammers include a depth rod.

Use it to avoid drilling deeper than necessary — especially in structural elements.

Common Signs You Should Stop Drilling

Sometimes conditions indicate that continuing is not safe or efficient.

Stop drilling if:

| Sign | Meaning | Action |

| Concrete begins to crack | Structure under stress | Stop immediately and reassess placement |

| Drill loses power or overheats | Bit or motor overheating | Pause and cool both drill + bit |

| Water becomes discolored with rust | You may be cutting major reinforcement | Consider relocating hole |

| You encounter extremely thick steel | Structural rebar bundle or tension cable | Do not continue — call a professional |

Not all steel inside concrete is rebar.

Some structures contain prestressed tension cables, which must never be cut.

Cutting these can cause:

- Loss of building strength

- Sudden cable recoil (dangerous injury risk)

If you suspect a tensioned system: stop and consult a structural engineer.

Concrete Drilling Safety and Efficiency Checklist

Before drilling:

- ✅ Put on goggles, gloves, ear protection, and a dust mask.

- ✅ Scan for rebar with a rebar detector or stud finder.

- ✅ Confirm hole location does not interfere with electrical or plumbing lines.

- ✅ Select appropriate drill type (hammer drill or rotary hammer).

- ✅ Attach a carbide-tipped masonry bit to begin.

When rebar is hit:

- ✅ Stop drilling immediately.

- ✅ Switch to a rebar-cutting bit.

- ✅ Turn hammer function off.

- ✅ Use steady pressure and apply water for cooling.

- ✅ Drill through the steel.

After rebar penetration:

- ✅ Switch back to masonry bit.

- ✅ Resume hammer drilling to final depth.

- ✅ Clear debris and vacuum the hole before installing fasteners or anchors.

Frequently Asked Questions (FAQ)

1. Can I drill through rebar with a regular masonry bit?

No. Masonry bits are designed for concrete, not steel.

If used on rebar, they will overheat, dull, or snap.

2. Which is the best drill bit for drilling rebar?

A TCT (Tungsten Carbide Tipped) rebar-cutting bit or SDS rebar cutter bit is best for reinforced concrete applications.

3. Should hammer mode stay on when drilling through steel?

No.

Turn hammer mode OFF when drilling through steel.

Hammering during steel cutting can damage the bit.

4. Do I need a rotary hammer, or will a hammer drill work?

- A hammer drill is enough for small holes (e.g., installing wall anchors).

- A rotary hammer is necessary for large/deep holes or thick concrete slabs.

5. Can drilling through rebar weaken the structure?

Yes, depending on location.

Avoid drilling into:

- Load-bearing beams

- Columns

- Structural slab reinforcement patterns

When unsure → Consult a structural engineer.

Conclusion

Drilling through concrete that contains rebar is absolutely possible — if done correctly. The key is understanding that concrete and rebar require different drill bits, speeds, and techniques.

To recap the core process:

- Scan for rebar before drilling to avoid structural complications.

- Start with a masonry bit to drill through the concrete.

- When you hit rebar:

- Stop

- Switch to a rebar-cutting bit

- Turn off hammer mode

- Use slow speed and steady pressure

- Apply water to keep the bit cool

- Stop

- Once through the steel:

- Switch back to the masonry bit

- Resume hammer drilling to final depth.

- Switch back to the masonry bit

- Clean and finish the hole for maximum holding strength.

With the right tools, proper safety precautions, and patience, even beginners can accomplish clean, professional-quality holes in reinforced concrete.

Hi, I’m Charles Larson. We do everything we can to support our readers with hundreds of hours of research and comparison testing to ensure you find the perfect tool for your workshop.